Quick Links:

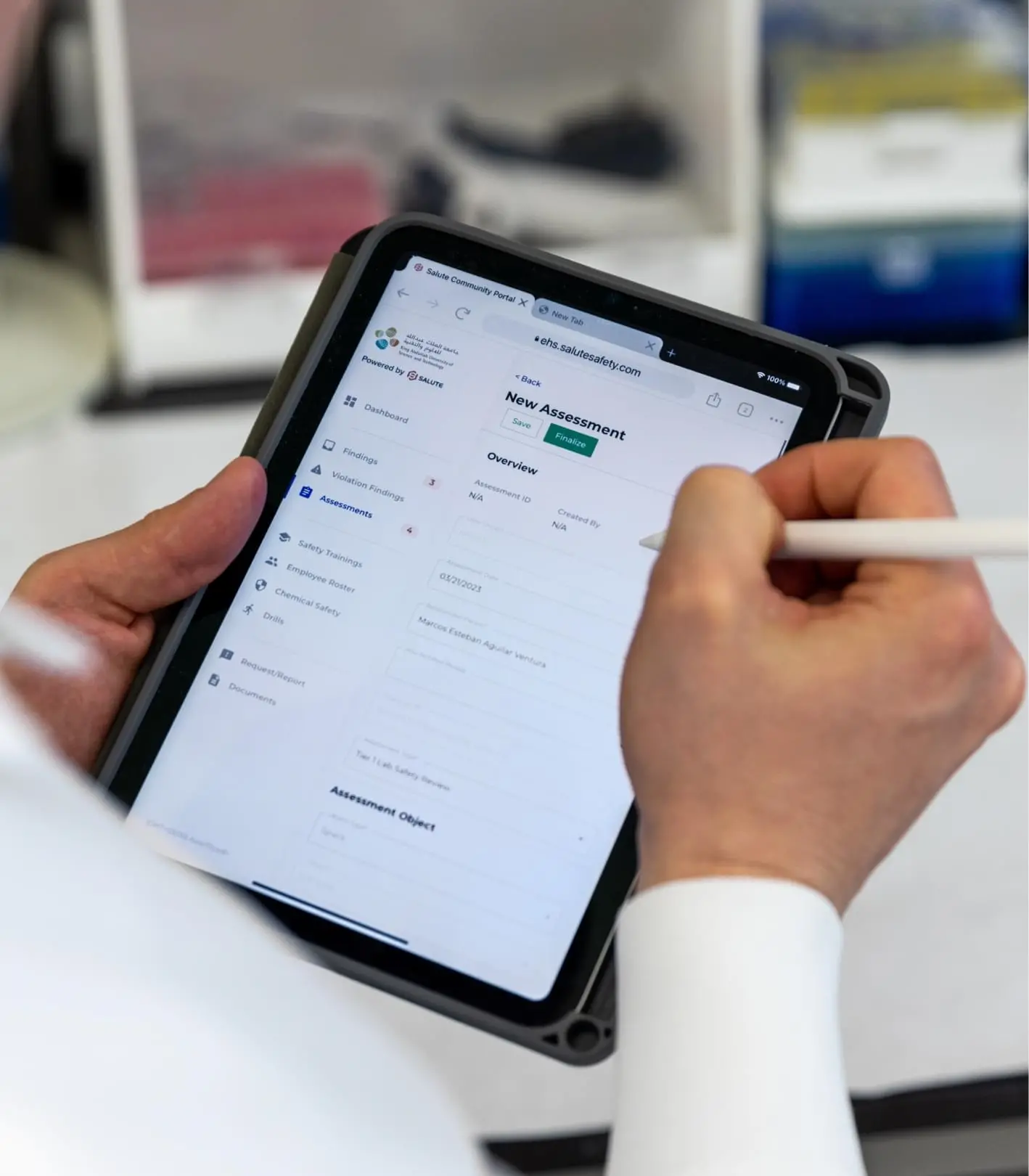

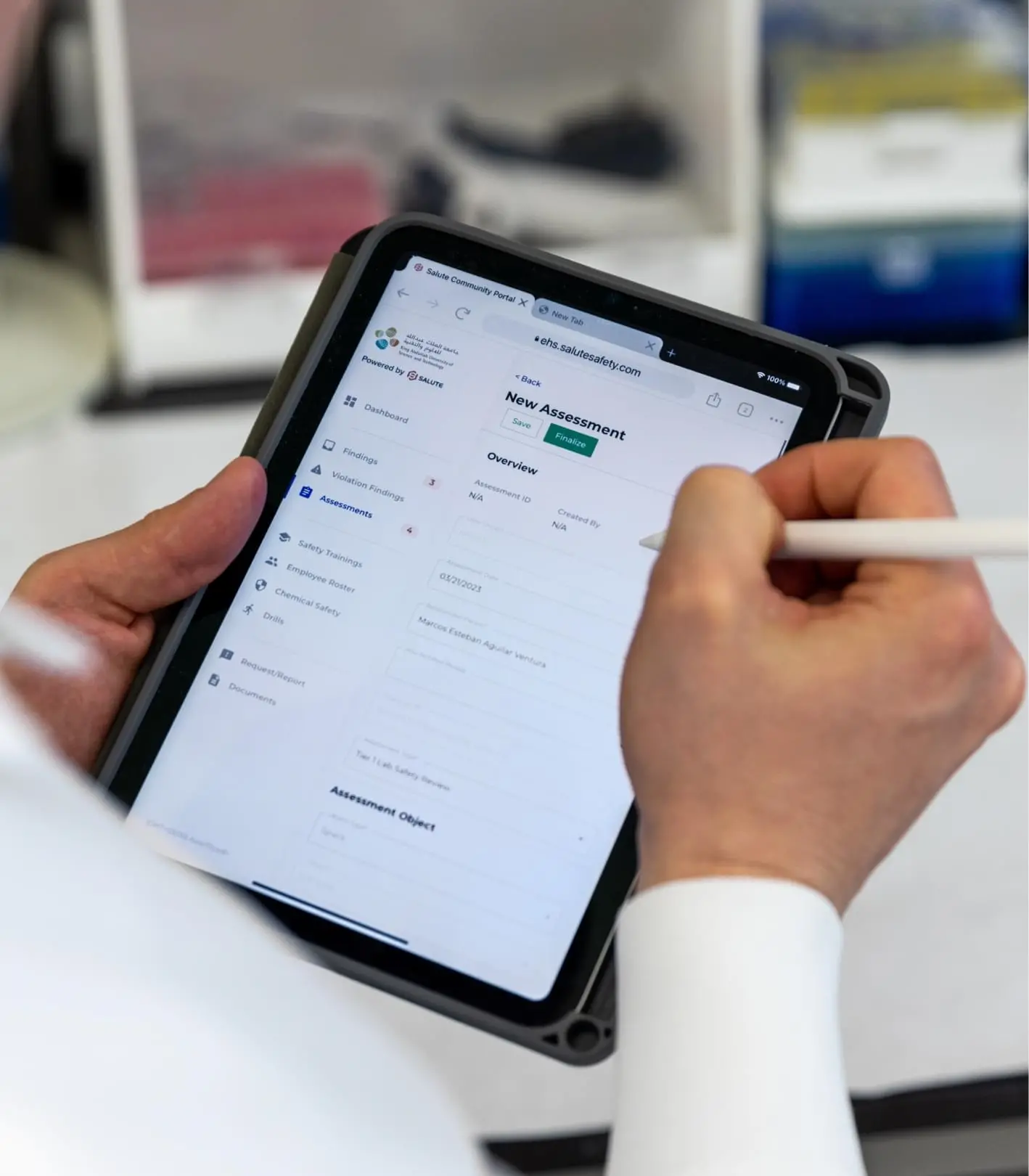

Assessments are used in research safety to conduct Lab Review Self Assessments, Lab Safety Assessments conducted by HSE, and Specialized Risk Assessments.

Lab assessments provide a coordinated and consistent approach to assess compliance, verification of controls, safety performance, correct issues and prioritize areas for improvement with respect to laboratory safety.

Some assessments are a unique and powerful tool that enables you to complete safety checklists and record safety observations and comments.

Current assessments in RST:

The Lab Safety Review consists of a simple and comprehensive checklist that is completed by the LSR or lab users. The checklist has questions about engineering and administrative controls, PPE, storage and housekeeping, general safety, emergency readiness and safety culture.

This tool is accessible to all lab users. It enables the lab users to conduct safety assessments, prevent safety issues, and keep a record of continuous safety improvements.

HSE conducts lab safety assessments for all KAUST laboratories, our main aim is to support research, ensure work is done in a safe environment and monitor safety compliance. The frequency of each inspection is driven by risk and the hazards in each laboratory. During the scheduled visit, HSE will inspect the laboratory using a specialized Salute assessment checklist that covers all the general safety aspects inside the lab. Findings/Actions, which are the main outcome of these assessments, are used to make sure that issues identified during the inspection are properly documented, tracked, analyzed, and to ensure that any required follow-up is completed.

HSE specific assessments for lasers, radiation, occupation health and other assessments specialized to control hazards and mitigate risks.

The Health and Safety department in collaboration with various department proponents undertake a yearly exercise to identify common hazards that the department as a whole encounter during their routine work. These hazards could be present in the vicinity or surroundings of their working environment or arise as a result of undertaking a specific activity. A risk assessment of the identified hazards is completed, and controls are suggested based on the level of risk. The number and extent of controls suggested are in line with the principle of keeping the risk as low as reasonably practicable. The implementation status of the control measures is followed through periodically to ensure implementation before the agreed deadline.

The objective of an inspection is to identify non-conformities for action and resolution, with a purpose to reduce the risk of incidents/accidents and potential adverse health consequences. Inspections are an important surveillance activity as part of a comprehensive health and safety program. Through these inspection activities we are proactively managing risks; providing the tools/guidance to promote safe work practices and a healthy work environment in accordance with KAUST standards. During an inspection, a non-conformity from the required standard is identified and corrective actions are assigned based on risk. We endeavor to work with our stakeholders to reduce the number of reported incidents/accidents. The Health and Safety inspection program covers project sites, construction sites, work permit activities, KAUST facilities and retail outlets such as food establishments and salons/barber shops. Documentation and follow-up is key to identify and track the closure of non-conformities, and specifically those that are aligned with Key Performance Indicators (KPIs) that HSE is tracking and analyzing.

An audit can be defined as an objective, systematic and critical evaluation of the health and safety management system. Audits are classified as a form of active monitoring. It aids in proactively managing risk and adding value to the organizations operation. The KAUST Health and Safety management system is certified to the ISO 45001 standard. A health and safety internal audit of all the departments are conducted by KAUST HSE on an annual basis.

KAUST HSE undertake assessments of various facilities including swimming pools and salons/barber shops and other public health assessments as required which may impact public health. Parameters are monitored for recreational water quality (e.g., chemical and microbiological parameters). Recreational water quality assessments are planned for all swimming pools at KAUST where community members have access. Personal hygiene, environmental sanitation and infection prevention and control (IPAC) parameters are monitored at the salons/barber shops. Non-conformities may include adverse microbiological parameters, chemical imbalances and/or health and safety non-conformities. Corrective actions are assigned for action based on risk and subsequent interventions are followed up until close-out. Documentation and follow-up is key to identify and track the closure of non-conformities, and specifically those that are aligned with Key Performance Indicators (KPIs) that HSE is tracking and analyzing.

The Retail Food Safety & Quality assessment is a risk based verification activity conducted by HSE as part of the Food Safety Management System oversight process to identify non-conformities targeted at preventing foodborne illness and reducing consumer complaints at KAUST.The assessment process uses a best practice and regulatory framework using risk based criteria to focus on Good Hygiene Practices GHPs and/or Hazard Analysis Critical Control Points HACCP that align with KAUST’s Food Safety & Quality Code; also serving as a verification process of the retailers internal inspection/audit process. Key focus areas of the assessment will include food handling, operation & maintenance, cleaning and sanitizing, commodities, and the identification of health hazards.Documentation and follow-up is key to identify and track the closure of non-conformities, and specifically those that are aligned with Key Performance Indicators (KPIs) that HSE is tracking and analyzing.

The intent of these inspections is to ensure that buildings are being maintained and used in a manner which does not compromise any active or passive fire protection measures. Where there are items which are seen as areas of non-compliance with adopted codes and standards, they will be reported to the responsible stakeholders for rectification.

This fire safety inspection has been undertaken by KAUST Fire Protection team to assist the responsible person in complying with the obligations to provide and maintain a safe workplace. The purpose of this inspection is to provide an assessment of the risk to life and property from fire in these premises and where appropriate, to make recommendations to ensure compliance with applicable fire safety legislation and KAUST policies and procedures. The inspection report does not address the risk to property or business continuity from fire unless specifically stated.

The objective of this inspection is to conduct visual inspections of the panels, devices and equipment to ensure that all Fire Protection systems are properly functional. In the event of a fire, these systems provide the alert signal for evacuation to the occupant and control and/or suppress the fire in the facility. Examples: Fire Detection & Alarm system, Fire Sprinkler System, Fire Pump, Stand Pipes and fire hose cabinets, clean agent fire extinguishing systems, Kitchen hood fire extinguishing systems CO2 fire extinguishing systems etc.

The purpose of internal assessment is ensure that all the Fire Protection systems are inspected, maintained, serviced and tested at regular intervals as per applicable codes / standards and manufacturer’s requirements. This program ensures that the qualified and trained personnel, suitable tools and equipment are available to carry out the required testing and maintenance of Fire Protection systems. Records of inspection and testing are collected from the service providers when deemed necessary.

The aim of this inspection is to ensure that all the activities at the construction, alteration and demolition structures/buildings are conducted safely in accordance with NFPA 241. This program also includes the inspection of temporary offices, sheds and storage facilities at the construction sites. The purpose of this program is to minimize the risk of injuries or death to persons or other life or of damage to property resulting from fires and related hazards.

The objective of this program is to conduct planned and unplanned inspection in the KAUST premises and report non-compliance items related to active and passive fire protection systems for rectification and adopted code compliance.