IMPORTANT:

Avoid acid storage with alcohols, azides, bases, bleach, cyanides, sulfides, nitrides, carbides, and metals. Preferably in a corrosive resistant material cabinet.

It is important to store flammable liquids only in specially designed flammable storage refrigerators/freezers or explosion-proof refrigerators/freezers. Do not store flammable liquids in standard (non- flammable rated) refrigerators/freezers. Standard refrigerators are not electrically designed to store flammable liquids. If flammable liquids are stored in a standard refrigerator, the build-up of flammable vapors can be in sufficient quantities to ignite when the refrigeratorʼs compressor or light turns on, resulting in a fire or an explosion.

Properly rated flammable liquid storage refrigerators/freezers have protected internal electrical components and are designed for the storage of flammable liquids. Explosion-proof refrigerators/freezers have both the internal and external electrical components properly protected and are designed for the storage of flammable liquids. Refrigerators and freezers rated for the storage of flammable materials will be clearly identified as such by the manufacturer. For most laboratory applications, a flammable storage refrigerator/freezer is acceptable. However, some operations may require an explosion-proof refrigerator/freezer

When transporting chemicals between laboratories or other buildings on campus, the following guidelines should be implemented for protection of people and the environment, and to minimize the potential for spills to occur.

Note: if you plan on transporting or shipping any hazardous chemicals off campus, be aware there are specific procedures, training and other legal requirements that must be followed. contact HSE at hse@kaust.edu.sa for more information.

Chemicals should be stored according to compatibility and hazard classes. Rather than store chemicals alphabetically, or by carbon number, or by physical state, etc., HSE recommends that you segregate them by hazard class first.

The potential hazards of storing incompatible chemicals together, and when an emergency occurs, include:

The benefits of chemical segregation by hazard class include:

There are a number of segregation schemes recommended in the literature by government agencies, chemical manufacturers, safety supply companies, and other universities. However, HSE recommends segregation of chemicals using a modified version of the International Air Transport Association (IATA) Hazard Class System. While this modified IATA system results in most common chemicals being segregated properly, there is no one system that solves all problems. The modified IATA system is less complicated than other segregation schemes and the information to make decisions of which hazard classes to use can easily be found in MSDSs, container labels, container markings and stickers, and other resources.

Please note that IATA hazard classes segregate chemicals according to the hazards posed during transportation and not necessarily based on health hazards. Keep in mind that chemicals do not always fall neatly into one hazard class and can pose multiple hazards – including both physical and health hazards (such as flammable liquid, corrosive liquid or flammable liquid, poison).

When you are making decisions on how to segregate, keep in mind the following:

Segregation of different chemical hazard classes (such as acids and bases) can occur in the same cabinet as long as there is some form of physical separation, such as using trays with high sides or deep trays. However, never store oxidizers and flammables in the same cabinet. Also, do not store compounds such as inorganic cyanides and acids in the same cabinet.

Once chemicals have been segregated, ensure everyone in the lab knows the process and what system is being used. It is best to clearly identify where chemicals in each hazard class will be stored by labeling cabinets with signs, or hazard class labels. These can be purchased from a safety supply company, created by lab personnel, or downloaded from theLab Safety Signs and Labels webpage.

If you need assistance with segregating your chemicals, contact HSE at hse@kaust.edu.sa.

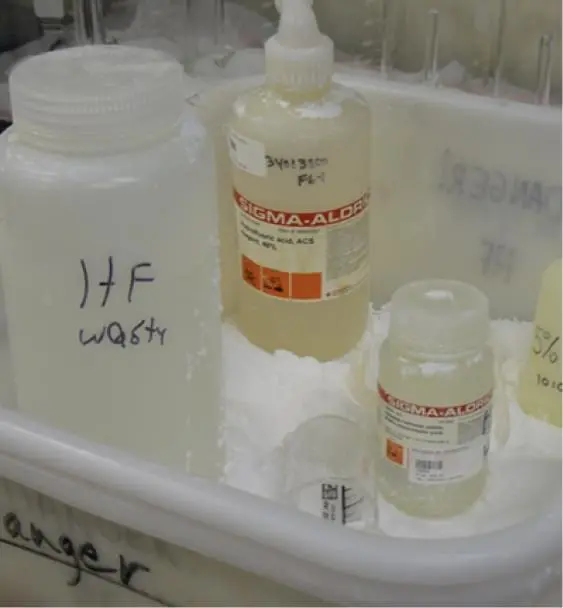

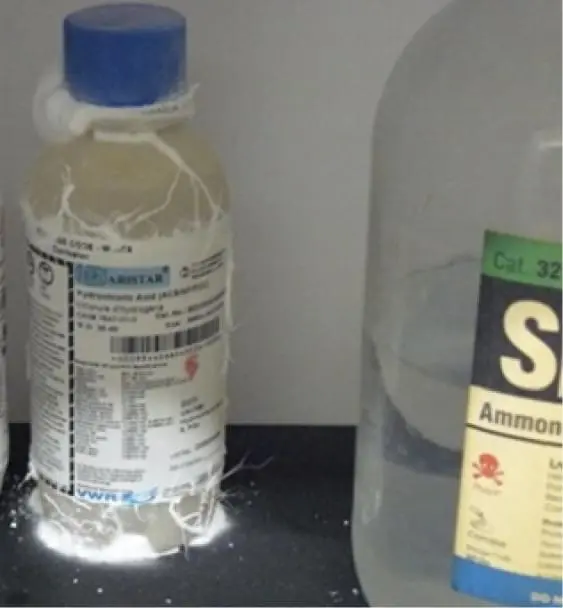

Determine the most dangerous hazards (explosions, fires, toxic gas generation, etc) and make it a priority to prevent those first! Ideal storage for Hydrofluoric acid – notice calcium carbonate powder in secondary container to neutralize excess HF that may drip down sides of bottles. Below are examples of acids and bases being incorrectly stored together in the same cabinet. Notice the formation of solid salts on the lids. Storing acids and bases in the same cabinet in secondary containers does not prevent the interaction of the vapors from reacting – one must store them in separate cabinets! Below is an example of a telltale sign that a corrosive material is present in a cabinet – rusted and corroded metal.

Avoid acid storage with alcohols, azides, bases, bleach, cyanides, sulfides, nitrides, carbides, and metals. Preferably in a corrosive resistant material cabinet.

All corrosive materials attack metal! Some hydroxides etch glass!

Some corrosive materials are also strong oxidizers and must be stored away from organic materials. Examples include Hydrogen peroxide, Chromic, Nitric, Perbromic, Perchloric, and Periodic acids.

The requirements for use of flammable storage cabinets are determined by the classification of the flammable liquids, the quantities kept on hand, the building construction (fire wall ratings), and the floor of the building the flammables are being stored on. As a general rule of thumb, if you have more than 40 liters (10 gallons) of flammable liquids, including materials in use, then you should store the flammable liquids in a properly rated flammable liquid storage cabinet. All flammable liquids not in use should be kept in a flammable liquid storage cabinet.

For stand-alone flammable liquid storage cabinets (as opposed to cabinets underneath fume hoods), there are vent holes on each side of the cabinet (called bung holes) that must have the metal bungs screwed into place for the cabinet to maintain its fire rating. Venting of flammable cabinets is NOT required, however, if a flammable cabinet is vented, it must be vented properly according to the manufacturerʼs specifications and NFPA 30.

Typically, proper flammable cabinet ventilation requires that air be supplied to the cabinet and the air be taken away via non-combustible pipes. If you are planning on venting your flammable storage cabinet, please contact HSE at hse@kaust.edu.safor more information.