Quick Links:

Due to the recent introduction of 3D printers, there is limited knowledge about all the potential health and safety issues with their use. Because of their size, relative low-cost, versatility and ease of use, these factors have further added to the desire of many labs wanting to add a 3D printer to their complement of equipment.

However this relatively rapid proliferation of 3D printer ownership on campus, with the various 3D printing processes involved and the wide variety of build materials used, combined with the experimental atmosphere of research, creates and makes 3D printer safety issues complex as one size does not fit all. This combination of factors has caused serious safety concerns.

Because of the differing 3D printer processes and the multitude of build materials available some clarity concerning standardized process definitions is needed. According to ISO/ASTM52900:2015 (en)*, there are seven differing process methods of 3D printing. Read the definitions and see the images below for an understanding of the various 3D printing processes available.

ISO – The International Organization for Standardization; ASTM – The American Society for Testing and Materials.

An Introduction to Additive Manufacturing/3D Printing

The Power Of 3D Additive Printing - In The Wild - GE

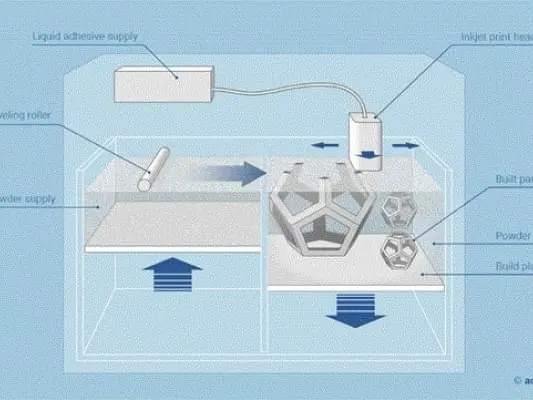

A process in which a liquid bonding agent is selectively deposited to join powdered materials

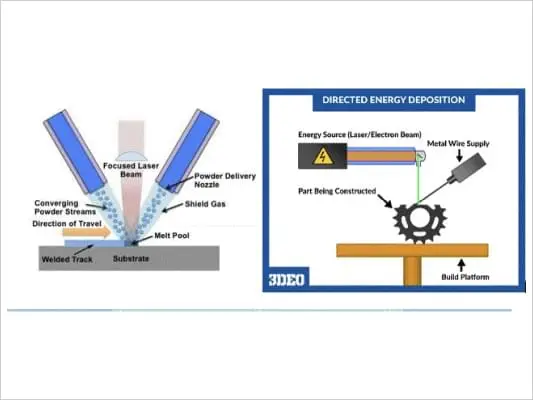

A process in which focused thermal energy (energy focused to melt materials being deposited) is used to fuse materials by melting them as they are being

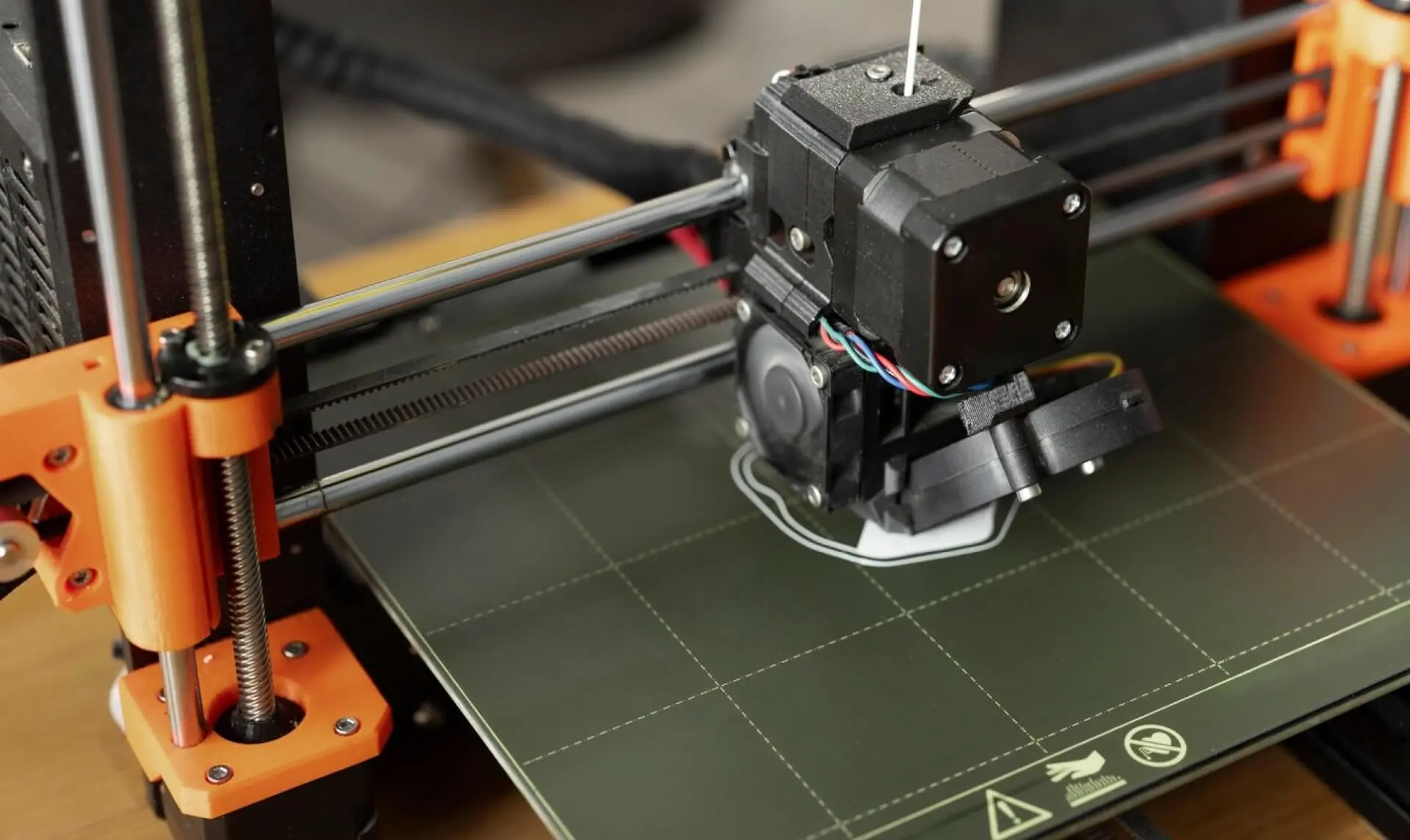

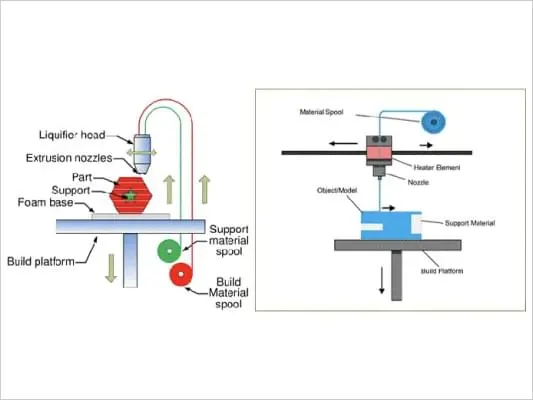

A process in which material is selectively dispensed through a nozzle or orifice. Material is usually heated and melted before it is extruded onto the object being created.

This process method is one of the favorite forms of bench top 3D printers.

Due to the overwhelming popularity of the Material Extrusion process in desk top 3D printers, a few acronyms associated with Material Extrusion are listed below.

FFF – Fused Filament Fabrication FDM – Fused Deposition Modeling

Both are Material Extrusion process methods that rely on filament that is melted and extruded.

Feed stock/build materials commonly used in Material Extrusion. ABS – Acrylonitrile Butadiene Styrene PLA – Polylactic Acid PC – Polycarbonate

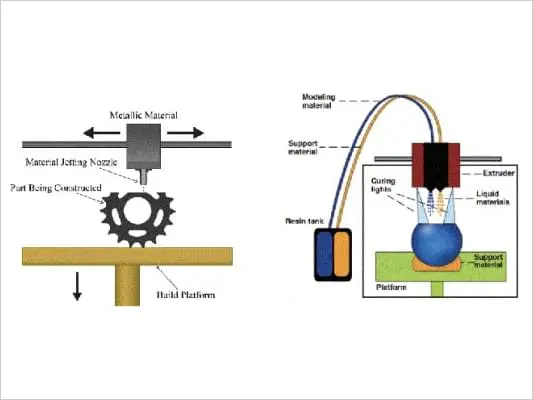

A process in which droplets of build material (photopolymer, wax, etc.) are selectively deposited.

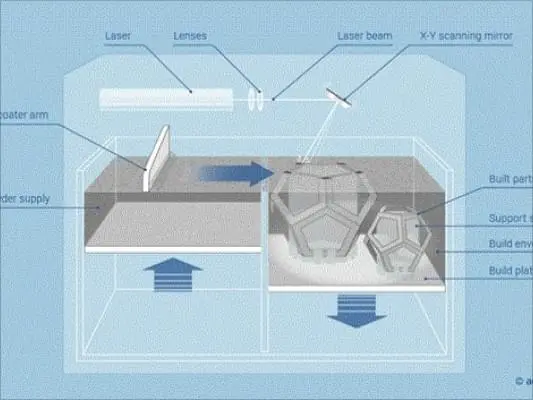

A process in which thermal energy selectively fuses regions of a powder bed.

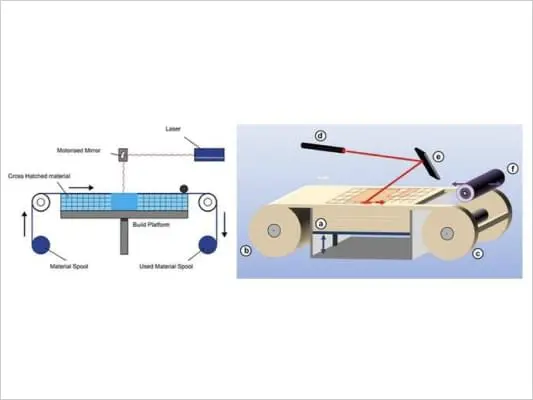

A process in which sheets of material are bonded (usually with an adhesive) to form a part.

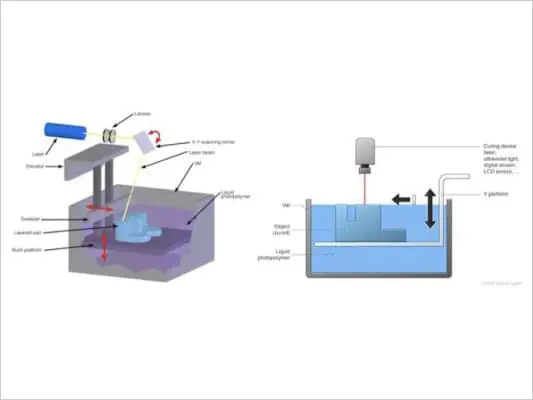

A process in which liquid photopolymer in a vat is selectively hardened (cured) by light activated polymerization.

Note: This process method is one of the favorite forms of desk top 3D printers.

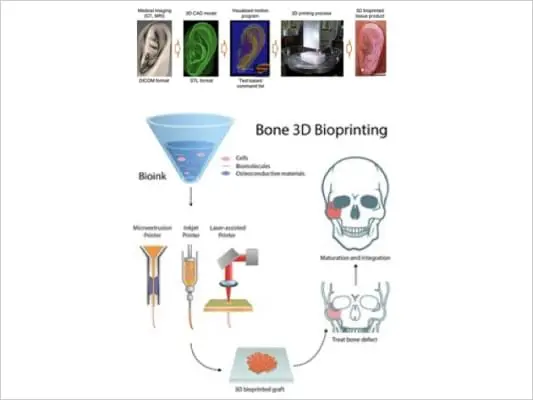

Bioprinting is not a separate process as described above. It utilizes the same processes and techniques described already but varies in the build materials utilizing biological materials (e.g. cells, growth factors, biomaterials, etc). Bioprinters may require Biosafety Level 2 (BSL-2) registration, contact hse@kaust.edu.sa if you have questions.