Quick Links:

Disposable nitrile gloves offer protection for short-term contact with small amounts of certain lab chemicals. However, they are not suitable for extended contact with chemicals.

Nitrile gloves are preferred over latex because of their chemical resistance, their tendency to visibly rip when punctured, and to prevent possible latex allergies.

In addiKon to their chemical resistance profile, another reason that nitrile gloves are used instead of latex is to avoid skin allergies that can be caused by the proteins in the latex rubber. It is possible, however, for some individuals to be sensitive to the accelerators (chemical addiKves) in nitrile. Please report any allergies to reportit.kaust.edu.sa for recommendations and support.

Glove manufacturers provide more information about glove chemical resistance based on permeation breakthrough time, boiling point, and concentration.

See example from Kimberly-Clark

The chemical warehouse stock these brands that comply with the EN ISO 374.

| MM # | Description | Size | Brand | Supplier |

|---|---|---|---|---|

| 3000000992 | NITRILE GLOVES | Medium | FISHER | FISHER UK |

| 3000000994 | NITRILE GLOVES | Large | FISHER | FISHER UK |

| 3000005637 | NITRILE GLOVES | Small | MICROFLEX | FISHER UK |

| 3000005946 | NITRILE GLOVES | Small | FISHER | FISHER UK |

| 3000010169 | NITRILE GLOVES | XL | FISHER | FISHER UK |

| 3000012093 | NITRILE GLOVES | Large | FISHER | FISHER UK |

| 3000003493 | NITRILE GLOVES | XL | Kimberly-Clark | FISHER US |

| 3000003883 | NITRILE GLOVES | Large | FISHER | FISHER UK |

| 3000010167 | NITRILE GLOVES | Medium | VWR | VWR UK |

| 3000011680 | NITRILE GLOVES | Small | VWR | VWR UK |

The EN ISO 374 standard ensures consistency in glove testing and helps users and safety professionals as they determine their chemical protection needs. Glove materials are evaluated on three criteria when exposed to chemicals: Penetration, Permeation and Degradation. The following information can be displayed in the product specifications or directly in the packing material.

The EN ISO 374 standard ensures consistency in glove testing and helps users and safety professionals as they determine their chemical protection needs. Glove materials are evaluated on three criteria when exposed to chemicals: Penetration, Permeation and Degradation. The following information can be displayed in the product specifications or directly in the packing material.

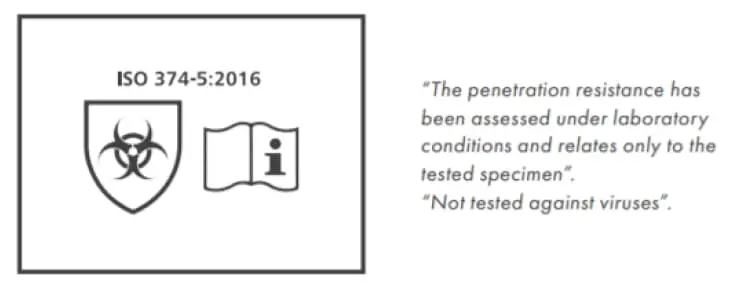

Gloves claiming protection from bacteria and fungi must carry the following pictogram in the packing material:

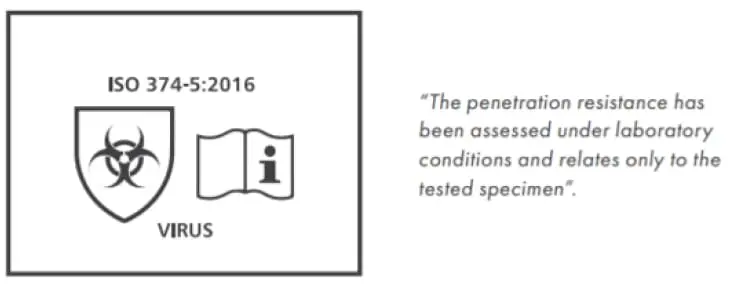

Gloves claiming protection from viruses require additional penetration testing according to ISO 16604:2004 and must carry the following pictogram in the packing material:

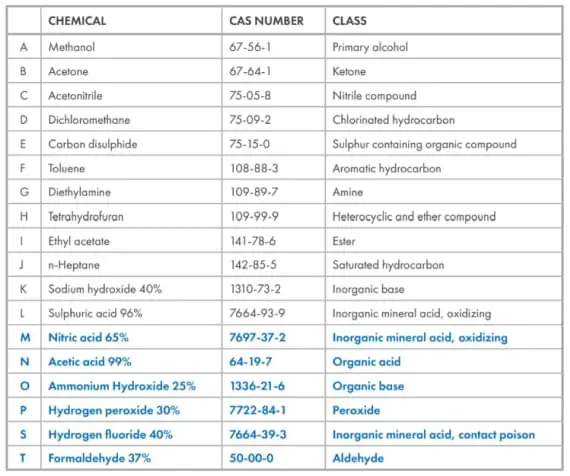

The rubber and plastic films in gloves are the barriers to chemicals. It is therefore necessary to measure breakthrough times, or the time taken for the hazardous liquid to come in contact with the skin. Each chemical tested is classified in terms of breakthrough time performance level 0 to 6.

| BBT (mins) | Performance Level |

|---|---|

| >10 | Level 1 |

| >30 | Level 2 |

| >60 | Level 3 |

| >120 | Level 4 |

| >240 | Level 5 |

| >480 | Level 6 |

Sometimes chemical protective gloves can act as sponges, soaking up the liquids and holding them against the skin. This degrades the glove. Degradation is the change in one or more physical characteristics of a glove caused by contact with a chemical. Indications of degradation are flaking, swelling, disintegration, embrittlement, colour change, dimensional change, appearance, hardening, softening, etc.

For more information please contact hse@kaust.edu.sa.